Engineer service HIgh quality guaranteed high temperature baghouse

Engineer service HIgh quality guaranteed high temperature baghouse

| Packaging: | Standard export packing: in nude packing for filter body, necessary protection for insulating layer, carton packing for filter bags, etc |

|---|---|

| Brand: | CNP |

| Place of Origin: | Tianjin, China (Mainland) |

Basic Info

Model No.: FPPF

Product Description

Engineer service HIgh quality guaranteed high temperature baghouse Specifications: 1. Without blowing pipe - easy for maintance

2. One chamber just need one Pulse Valve - cost save

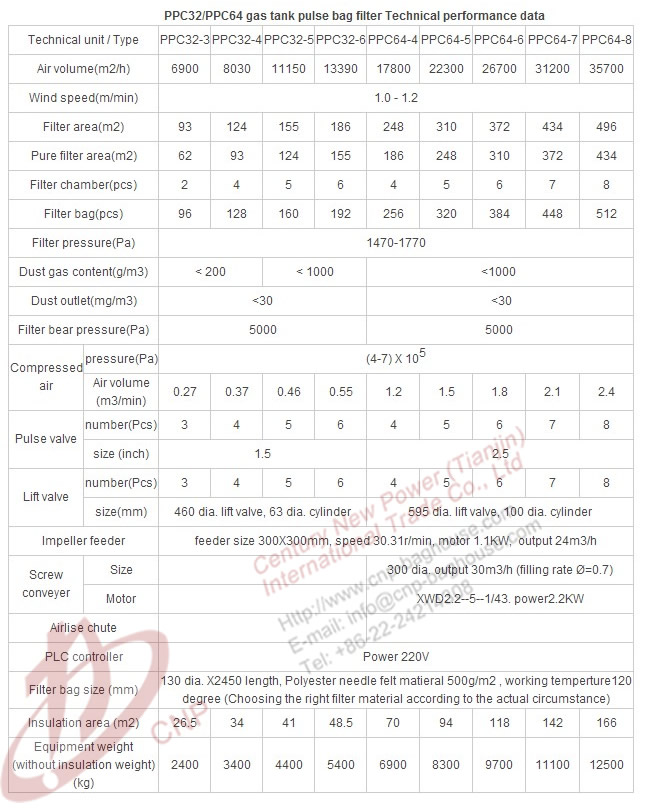

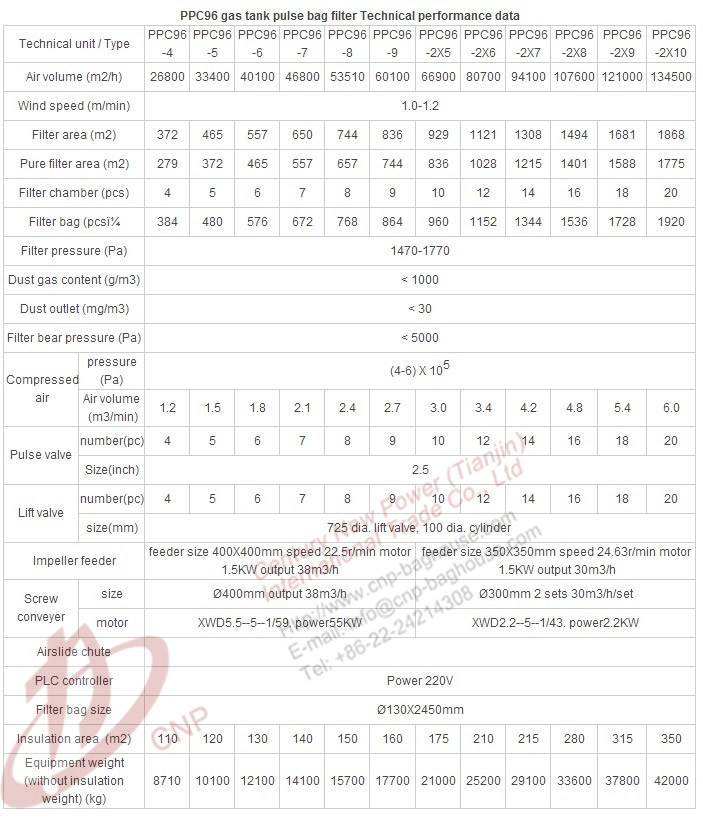

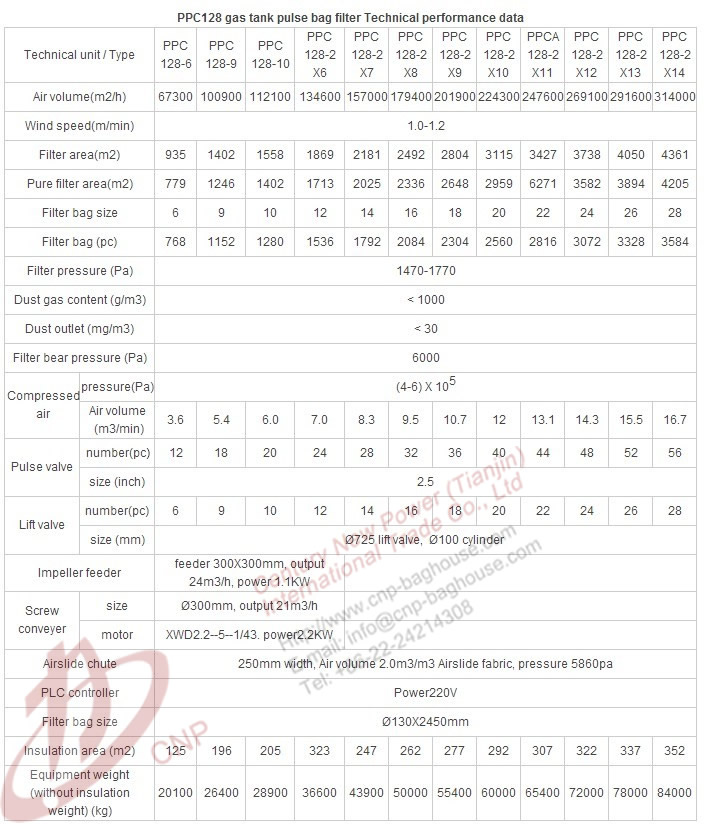

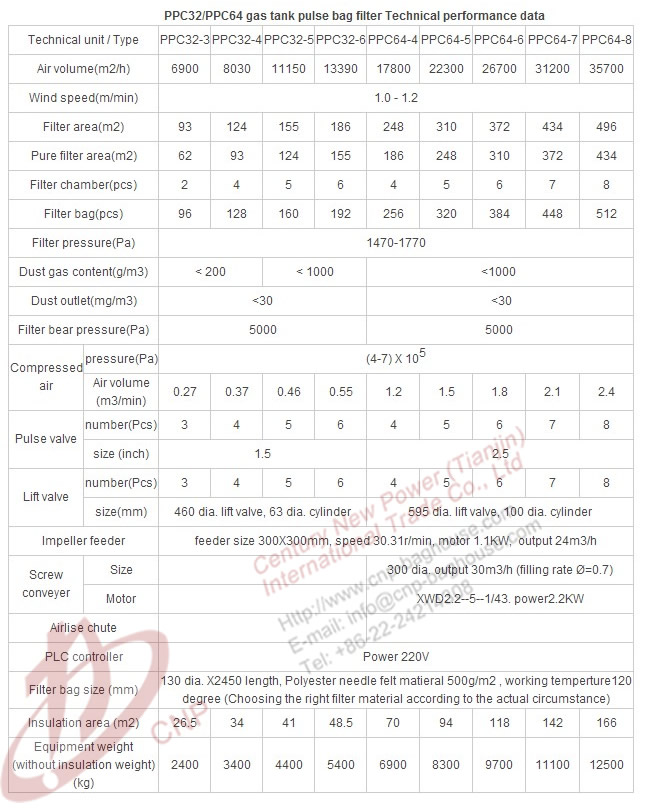

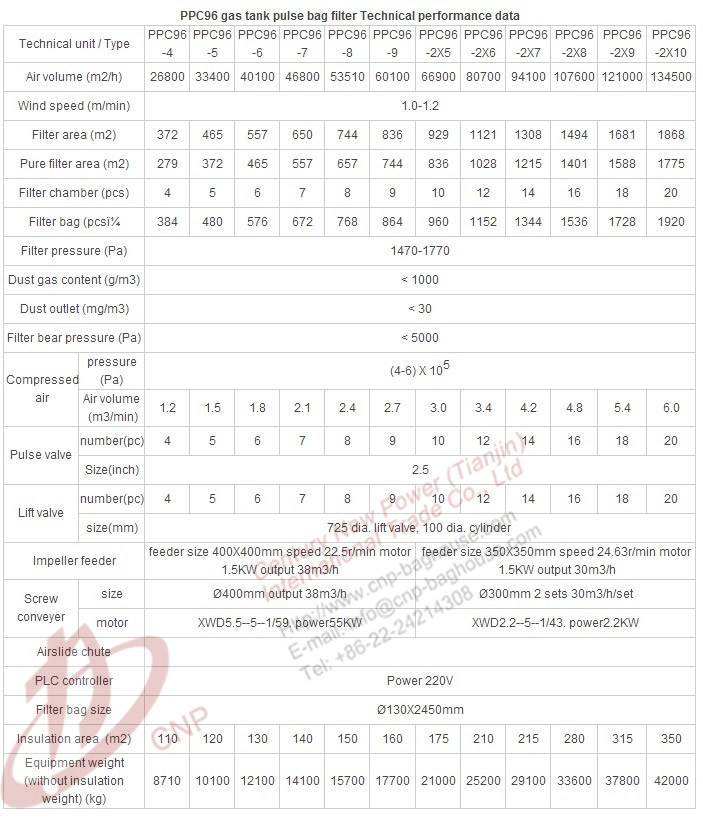

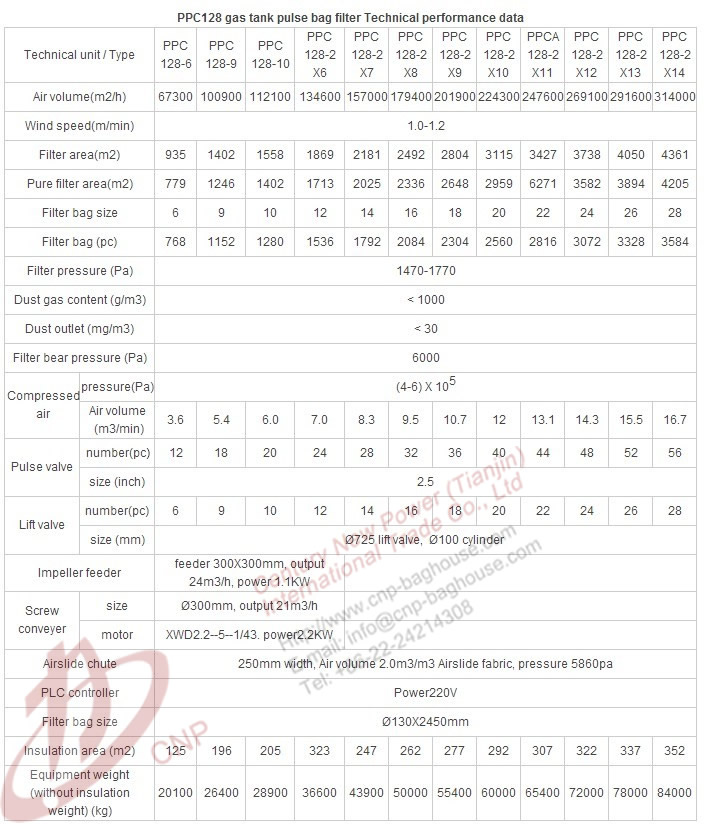

3. Large air volume suitable Product Description Introduction PPC gas tank pulse bag filter is using separate dust cleaning in every chamber by isolation. The every chamber of the pulse and soot cleaning cycle by soot cleaning program controller. So it can ensure the compressed air soot cleaning effect. Air tank pulse bag filter has the Filter bag number in 32, 64, 96, 128 bags per room. PPC air tank pulse bag filter is to meet more customer needs deal the large quantity, high concentration of dust powder. On the basis of the type FPPC filter, the PPC one increasing soot cleaning strength, improve the efficiency of dust removal. At the same time, it expand the application range of bag filter. The filter is mainly used for crusher, dryer, coal mill, raw meal grinding, cement mill dust removal equipment, building materials industry such as packaging machine, also it can be used as metallurgy, machinery, chemical industry, papermaking industry and other industrial and mining enterprises of dust collection and dust collecting. Five Technology Comprehensive Upgrade: 1. Gas wind inlet and outlet more uniform distribution

PPC air tank pulse bag filter is to meet more customer needs deal the large quantity, high concentration of dust powder. On the basis of the type FPPC filter, the PPC one increasing soot cleaning strength, improve the efficiency of dust removal. At the same time, it expand the application range of bag filter. The filter is mainly used for crusher, dryer, coal mill, raw meal grinding, cement mill dust removal equipment, building materials industry such as packaging machine, also it can be used as metallurgy, machinery, chemical industry, papermaking industry and other industrial and mining enterprises of dust collection and dust collecting. Five Technology Comprehensive Upgrade: 1. Gas wind inlet and outlet more uniform distribution

Expand the filter body up and down volume to reduce the resistance, the structure of bag filter makes the flow more smoothly, gently and evenly. Increase the working life of Filter Bag media. 2. Soot cleaning more thoroughly

Adopting international advanced offline three soot cleaning way (filtration, dust, static), avoid dust "adsorption" again. 3. Design more flexible

It can increase the settling chamber design according to the working condition of demand. More extend the service life of filter bag , dust concentration can as high as 1000 g/Nm3. 4. More convenient to control

The PLC program controller, or smart controller instrument control the blowing, slag discharge, ect. In the same time, it can adjust by timing or by manually. The most guarantees the ash removal effect. Timing: set a time program, automatically clear dust room by room

Manual instructions: adopt the automatic control in normal working conditions. When a single room failure, it can random manual control switch. 5. More lower cost

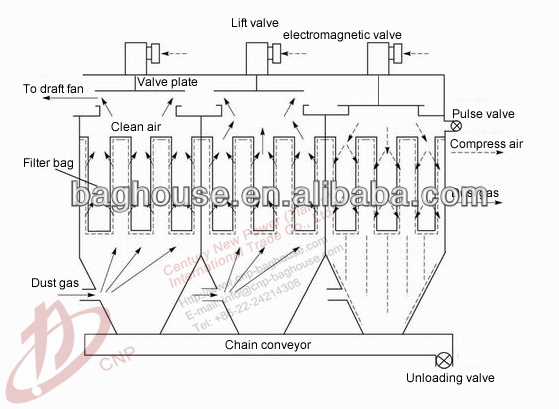

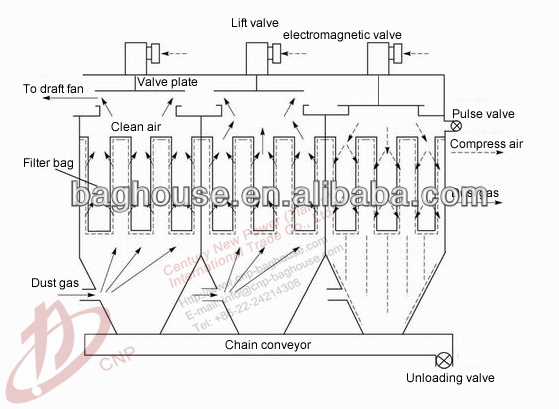

Chamber blowing ash removal: a Pulse valve can blow one room (the amount of filter bag 32, 64, 96pcs per room). Compared with ordinary filter injection, it decrease the number of pulse valve 6 to 20 times. STRUCTURE COMPOSITION PPC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, pulse valve, dragon frame, Screw conveyor, discharge valve, electrical control cabinet, air compressor, etc. All parts are made according to the national standards. The wiring terminal location set according to the requirements of customers. Please see the Amphenol connector in electrical controller operating instructions. Dust collection box include: filter bag chamber, dust subside chamber, clean air chamber, perforated plate, filter bag, filter cages. The design of bag filter will the 8000 pa pressure. Blowing system: the main trachea, spray pipe, pulse valve, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: One is direct connection discharge valve, the other is ash hopper connected the discharge valve through the conveying equipment.

Dust collection box include: filter bag chamber, dust subside chamber, clean air chamber, perforated plate, filter bag, filter cages. The design of bag filter will the 8000 pa pressure. Blowing system: the main trachea, spray pipe, pulse valve, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: One is direct connection discharge valve, the other is ash hopper connected the discharge valve through the conveying equipment.

Working principle Under the action of the main power fan , the dust gas enter into the dust subside chamber through air inlet. Dust gas is blocked flow board touch attack the airflow into the hopper. At the same time, air speed is slows down. Under the inertia and weight, the coarser particles directly into the dust discharger. Other light fine dust with air adsorb on the filter bag surface, the filtered clean gas through the filter bag into the box body and outlet. The PPC filter main body is separated into several air tank. There is a cylinder on each side outlet piping for lift valve. When the bag filter work after one cycle, the ash removal controller gives the signal, the first recess lift valve closed to cut off the flow of gas, enclosure of pulse valve open, with more than 0.4 Mpa compressed air into the net gas chamber, clear dust on the filter bag; When this action is completed, the lift valve to open, the chamber begin to work again, and one by one according to the above procedure complete soot cleaning action.

Under the action of the main power fan , the dust gas enter into the dust subside chamber through air inlet. Dust gas is blocked flow board touch attack the airflow into the hopper. At the same time, air speed is slows down. Under the inertia and weight, the coarser particles directly into the dust discharger. Other light fine dust with air adsorb on the filter bag surface, the filtered clean gas through the filter bag into the box body and outlet. The PPC filter main body is separated into several air tank. There is a cylinder on each side outlet piping for lift valve. When the bag filter work after one cycle, the ash removal controller gives the signal, the first recess lift valve closed to cut off the flow of gas, enclosure of pulse valve open, with more than 0.4 Mpa compressed air into the net gas chamber, clear dust on the filter bag; When this action is completed, the lift valve to open, the chamber begin to work again, and one by one according to the above procedure complete soot cleaning action.

Cement mill dust collection Gas tank pulse blowing Dust collector bag filter ******************** Please click the following product name to view more details: SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal fan REVERSE BLOW FILTER Dust Collector

Cement mill dust collection Gas tank pulse blowing Dust collector bag filter ******************** Please click the following product name to view more details: SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal fan REVERSE BLOW FILTER Dust Collector  FILTER BAG / Filter cage SCREW CONVEYOR Airslide fabric / HOSE PULSE VALVE UNLOADER FILTER FELT ********************

FILTER BAG / Filter cage SCREW CONVEYOR Airslide fabric / HOSE PULSE VALVE UNLOADER FILTER FELT ********************

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future Contact Information Please don't hesitate to contact me if there is anything we can do for you! We would like to help you slove the dedusting problem and supply the equipment to you Skype: cnp_crystal Whatsup; +86 13821106147 Send your inquiry to us! feedback with 12hours. Contact us if you need more details on High Temperature Baghouse. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Temperature Baghouse in Asphalt Plant、Asphalt Plant Dust Collector. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future Contact Information Please don't hesitate to contact me if there is anything we can do for you! We would like to help you slove the dedusting problem and supply the equipment to you Skype: cnp_crystal Whatsup; +86 13821106147 Send your inquiry to us! feedback with 12hours. Contact us if you need more details on High Temperature Baghouse. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Temperature Baghouse in Asphalt Plant、Asphalt Plant Dust Collector. If these products fail to match your need, please contact us and we would like to provide relevant information.

2. One chamber just need one Pulse Valve - cost save

3. Large air volume suitable Product Description Introduction PPC gas tank pulse bag filter is using separate dust cleaning in every chamber by isolation. The every chamber of the pulse and soot cleaning cycle by soot cleaning program controller. So it can ensure the compressed air soot cleaning effect. Air tank pulse bag filter has the Filter bag number in 32, 64, 96, 128 bags per room.

PPC air tank pulse bag filter is to meet more customer needs deal the large quantity, high concentration of dust powder. On the basis of the type FPPC filter, the PPC one increasing soot cleaning strength, improve the efficiency of dust removal. At the same time, it expand the application range of bag filter. The filter is mainly used for crusher, dryer, coal mill, raw meal grinding, cement mill dust removal equipment, building materials industry such as packaging machine, also it can be used as metallurgy, machinery, chemical industry, papermaking industry and other industrial and mining enterprises of dust collection and dust collecting. Five Technology Comprehensive Upgrade: 1. Gas wind inlet and outlet more uniform distribution

PPC air tank pulse bag filter is to meet more customer needs deal the large quantity, high concentration of dust powder. On the basis of the type FPPC filter, the PPC one increasing soot cleaning strength, improve the efficiency of dust removal. At the same time, it expand the application range of bag filter. The filter is mainly used for crusher, dryer, coal mill, raw meal grinding, cement mill dust removal equipment, building materials industry such as packaging machine, also it can be used as metallurgy, machinery, chemical industry, papermaking industry and other industrial and mining enterprises of dust collection and dust collecting. Five Technology Comprehensive Upgrade: 1. Gas wind inlet and outlet more uniform distributionExpand the filter body up and down volume to reduce the resistance, the structure of bag filter makes the flow more smoothly, gently and evenly. Increase the working life of Filter Bag media. 2. Soot cleaning more thoroughly

Adopting international advanced offline three soot cleaning way (filtration, dust, static), avoid dust "adsorption" again. 3. Design more flexible

It can increase the settling chamber design according to the working condition of demand. More extend the service life of filter bag , dust concentration can as high as 1000 g/Nm3. 4. More convenient to control

The PLC program controller, or smart controller instrument control the blowing, slag discharge, ect. In the same time, it can adjust by timing or by manually. The most guarantees the ash removal effect. Timing: set a time program, automatically clear dust room by room

Manual instructions: adopt the automatic control in normal working conditions. When a single room failure, it can random manual control switch. 5. More lower cost

Chamber blowing ash removal: a Pulse valve can blow one room (the amount of filter bag 32, 64, 96pcs per room). Compared with ordinary filter injection, it decrease the number of pulse valve 6 to 20 times. STRUCTURE COMPOSITION PPC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, pulse valve, dragon frame, Screw conveyor, discharge valve, electrical control cabinet, air compressor, etc. All parts are made according to the national standards. The wiring terminal location set according to the requirements of customers. Please see the Amphenol connector in electrical controller operating instructions.

Dust collection box include: filter bag chamber, dust subside chamber, clean air chamber, perforated plate, filter bag, filter cages. The design of bag filter will the 8000 pa pressure. Blowing system: the main trachea, spray pipe, pulse valve, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: One is direct connection discharge valve, the other is ash hopper connected the discharge valve through the conveying equipment.

Dust collection box include: filter bag chamber, dust subside chamber, clean air chamber, perforated plate, filter bag, filter cages. The design of bag filter will the 8000 pa pressure. Blowing system: the main trachea, spray pipe, pulse valve, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: One is direct connection discharge valve, the other is ash hopper connected the discharge valve through the conveying equipment.

Working principle

Under the action of the main power fan , the dust gas enter into the dust subside chamber through air inlet. Dust gas is blocked flow board touch attack the airflow into the hopper. At the same time, air speed is slows down. Under the inertia and weight, the coarser particles directly into the dust discharger. Other light fine dust with air adsorb on the filter bag surface, the filtered clean gas through the filter bag into the box body and outlet. The PPC filter main body is separated into several air tank. There is a cylinder on each side outlet piping for lift valve. When the bag filter work after one cycle, the ash removal controller gives the signal, the first recess lift valve closed to cut off the flow of gas, enclosure of pulse valve open, with more than 0.4 Mpa compressed air into the net gas chamber, clear dust on the filter bag; When this action is completed, the lift valve to open, the chamber begin to work again, and one by one according to the above procedure complete soot cleaning action.

Under the action of the main power fan , the dust gas enter into the dust subside chamber through air inlet. Dust gas is blocked flow board touch attack the airflow into the hopper. At the same time, air speed is slows down. Under the inertia and weight, the coarser particles directly into the dust discharger. Other light fine dust with air adsorb on the filter bag surface, the filtered clean gas through the filter bag into the box body and outlet. The PPC filter main body is separated into several air tank. There is a cylinder on each side outlet piping for lift valve. When the bag filter work after one cycle, the ash removal controller gives the signal, the first recess lift valve closed to cut off the flow of gas, enclosure of pulse valve open, with more than 0.4 Mpa compressed air into the net gas chamber, clear dust on the filter bag; When this action is completed, the lift valve to open, the chamber begin to work again, and one by one according to the above procedure complete soot cleaning action.

Cement mill dust collection Gas tank pulse blowing Dust collector bag filter ******************** Please click the following product name to view more details: SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal fan REVERSE BLOW FILTER Dust Collector

Cement mill dust collection Gas tank pulse blowing Dust collector bag filter ******************** Please click the following product name to view more details: SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal fan REVERSE BLOW FILTER Dust Collector  FILTER BAG / Filter cage SCREW CONVEYOR Airslide fabric / HOSE PULSE VALVE UNLOADER FILTER FELT ********************

FILTER BAG / Filter cage SCREW CONVEYOR Airslide fabric / HOSE PULSE VALVE UNLOADER FILTER FELT ********************

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future Contact Information Please don't hesitate to contact me if there is anything we can do for you! We would like to help you slove the dedusting problem and supply the equipment to you Skype: cnp_crystal Whatsup; +86 13821106147 Send your inquiry to us! feedback with 12hours. Contact us if you need more details on High Temperature Baghouse. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Temperature Baghouse in Asphalt Plant、Asphalt Plant Dust Collector. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future Contact Information Please don't hesitate to contact me if there is anything we can do for you! We would like to help you slove the dedusting problem and supply the equipment to you Skype: cnp_crystal Whatsup; +86 13821106147 Send your inquiry to us! feedback with 12hours. Contact us if you need more details on High Temperature Baghouse. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Temperature Baghouse in Asphalt Plant、Asphalt Plant Dust Collector. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Dust collector > Other Dust collector

Premium Related Products

Other Products

Hot Products

Dust collector machine and baghouse filterBag Type Wood Washable Pocket FiltersComfortable cyclone separator priceMini cyclone separator dust collector24v miniature cheap solenoid pulse ValveCement grain pellet ice shaftless sand flexible screw conveyorBulk cement trailer self unloading equipment parts the PU coated Airslide Aeration hoseHigh temperature dust exhaust fan dust collector fan blowerAramid Airslide Fabric / BeltBulk material bottom rotary discharge valveOrgano silicone filter bag cageSulphide dust treatment PPS low price filter bagPolyester filter fabric stainless steel fiber needle feltCylindrical cyclone pulse jet silo dust collection bag filterCement industry plant dust pollution control the dust collector pulse vibration bag filterSimple bag filter AIO machine portable wood dust collector