Bag type industrial dust collection filter

Bag type industrial dust collection filter

| Delivery Time: | 30 Days |

|---|

| Packaging: | Standard export packing: in nude packing for filter body, necessary protection for insulating layer, carton packing for filter bags, etc |

|---|---|

| Brand: | CNP |

| Place of Origin: | China (Mainland) |

Basic Info

Model No.: ZC

Product Description

Small pulse jet steel silo woodworking Dust collector bag filter Be the biggest supplier of Dust filter Secure Payment service support !! We are Trade Assurance supplier! Order us from your alibaba account directly.  Please click following picture to see our more information about cyclone and bag type Dust Collector equipment introduction:

Please click following picture to see our more information about cyclone and bag type Dust Collector equipment introduction:  Product Description Industry application impulse bag type dust collector

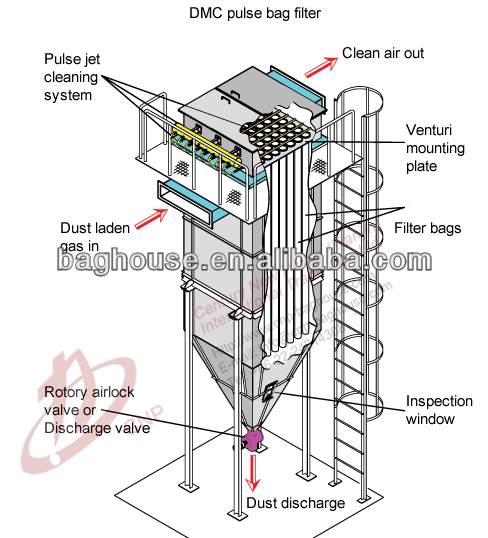

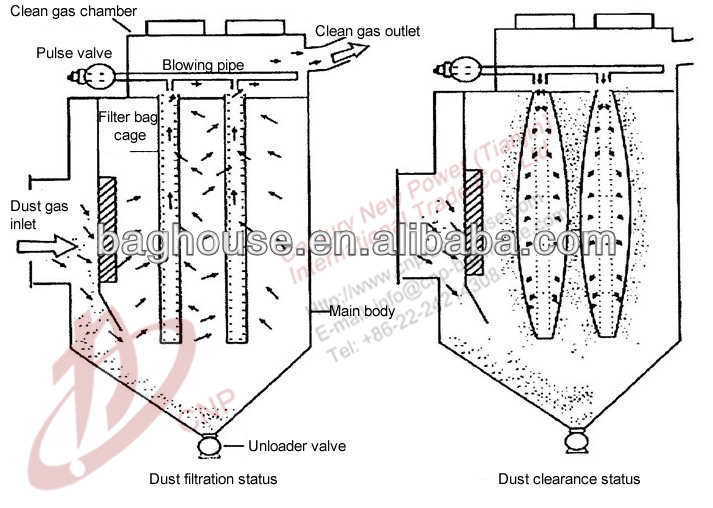

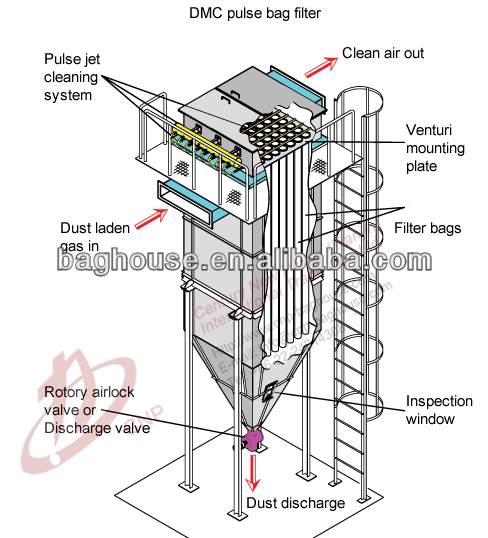

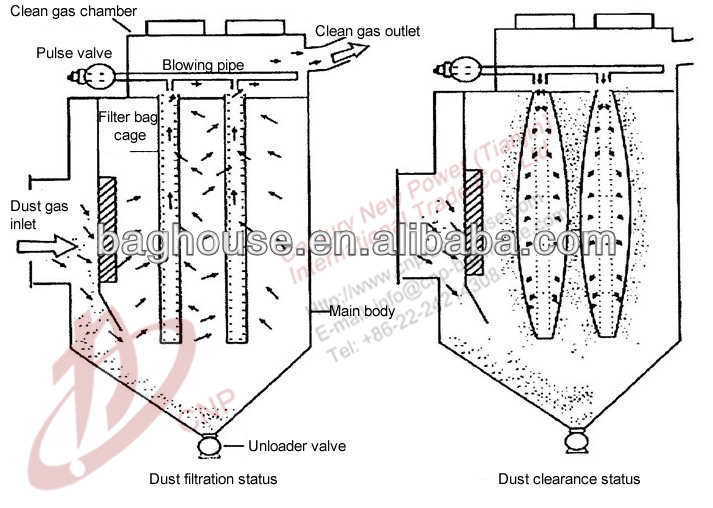

Product Description Industry application impulse bag type dust collector  DMC pulse bag filter is a kind of small and medium-sized pulse jet dust collector. Reasonable structure design to realize efficient dust removal and small resistance running. To adopt pulse blowing dust, soot cleaning effect is better. The advantage is reliable operation, easy maintenance and management. This kind of bag filter always widely used in cement, metallurgy, electric power, chemical and other industries of dust gas purification and material recycling. DMC pulse bag dust catcher are composed by the filter chamber housing, clean air chamber enclosure, Filter bag and Filter cage, pulse injection device, ash hopper, Screw conveyor and discharger, etc. Structure Composition DMC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, Pulse Valve, screw conveyor, discharge valve, electrical control cabinet, air compressor, Filter Bag, filter cages, etc. All parts are made according to the national standards and customer's requirement. Blowing system: the spray pipe, Pulse valve, venturi, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: motor, reducer, screw conveyer, unloader, etc. Working principle

DMC pulse bag filter is a kind of small and medium-sized pulse jet dust collector. Reasonable structure design to realize efficient dust removal and small resistance running. To adopt pulse blowing dust, soot cleaning effect is better. The advantage is reliable operation, easy maintenance and management. This kind of bag filter always widely used in cement, metallurgy, electric power, chemical and other industries of dust gas purification and material recycling. DMC pulse bag dust catcher are composed by the filter chamber housing, clean air chamber enclosure, Filter bag and Filter cage, pulse injection device, ash hopper, Screw conveyor and discharger, etc. Structure Composition DMC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, Pulse Valve, screw conveyor, discharge valve, electrical control cabinet, air compressor, Filter Bag, filter cages, etc. All parts are made according to the national standards and customer's requirement. Blowing system: the spray pipe, Pulse valve, venturi, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: motor, reducer, screw conveyer, unloader, etc. Working principle  Sales Performance As the best-selling brand of small size dust collector of our company, DMC pulse bag dust collector has the device of the quantity of goods more than 500 units so far this year 2013. Which is used for cement plant library, belt corridor for 83 units; used in mining, building materials industries of the crusher, belt conveyor unloading point for 75 units; used in complete set of packaging machine for 120 sets; used in chemical industry of small vibrating sieve for 65 sets; used in sieve drum filter, mechanical machining, grinding machine, sandblasting room and other industries for 150 sets; DMC pulse bag dust collector is favored by many industrial customer friends. The main reason is the reasonable structural design, reliable performance, easy maintenance and management. As an example: In 2010 year, we provide DMC - 183 type bag dust collector for AL Haribiaha cement plant, since the installation run till now, operation is very stable, soot cleaning effect is very good!

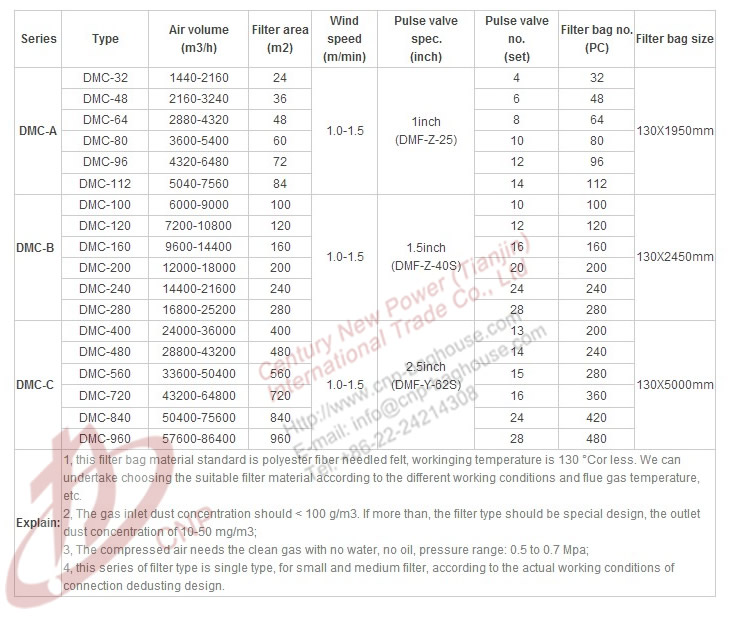

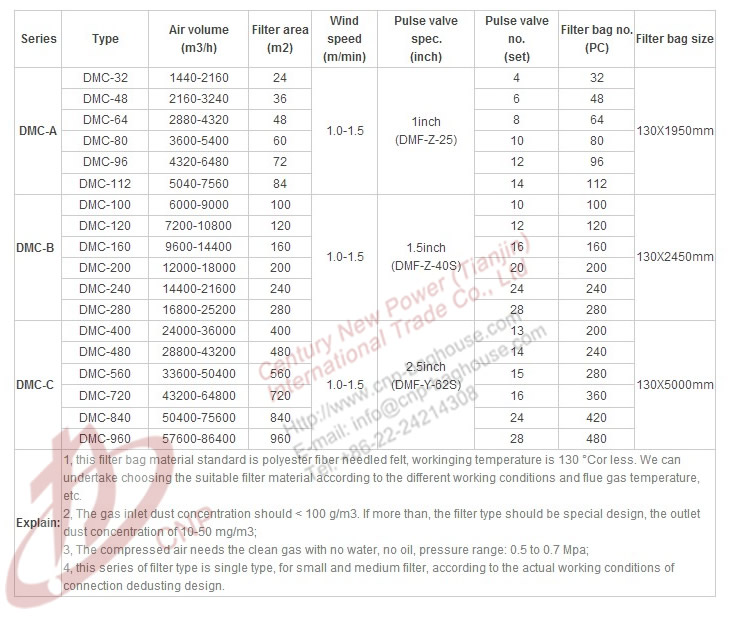

Sales Performance As the best-selling brand of small size dust collector of our company, DMC pulse bag dust collector has the device of the quantity of goods more than 500 units so far this year 2013. Which is used for cement plant library, belt corridor for 83 units; used in mining, building materials industries of the crusher, belt conveyor unloading point for 75 units; used in complete set of packaging machine for 120 sets; used in chemical industry of small vibrating sieve for 65 sets; used in sieve drum filter, mechanical machining, grinding machine, sandblasting room and other industries for 150 sets; DMC pulse bag dust collector is favored by many industrial customer friends. The main reason is the reasonable structural design, reliable performance, easy maintenance and management. As an example: In 2010 year, we provide DMC - 183 type bag dust collector for AL Haribiaha cement plant, since the installation run till now, operation is very stable, soot cleaning effect is very good!  Specifications Performance Parameter DMC pulse jet bag filter technical parameters:

Specifications Performance Parameter DMC pulse jet bag filter technical parameters:  Due to the different industries, the DMC pulse bag filter has the different applicable conditions. Please be sure to tell us about your needs, we are very happy to provide surveying and design for you by free, to achieve the best and safety solution of dust collection. Trade Shows f application

Due to the different industries, the DMC pulse bag filter has the different applicable conditions. Please be sure to tell us about your needs, we are very happy to provide surveying and design for you by free, to achieve the best and safety solution of dust collection. Trade Shows f application

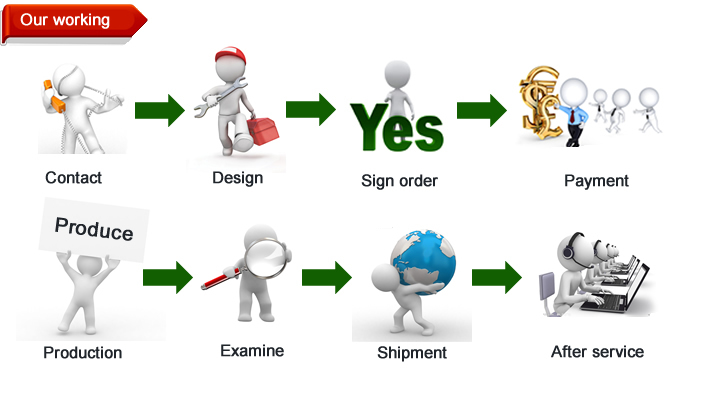

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future. Introduction Revolving reverse blowing bag-type filter, It is using rotating air nozzle, one by one to reverse blow filter bag to dedust bag filter. It has the advantages of simple structure, stable performance, blow air access convenient and small mainte- nance workload. To adopt outside filter type principle, we can divide revolving reverse blowing bag filter according to the different distri- bution in the cross section of the filter bag, flat bag filter, rotary blowback bag filter and rotary blowback bag filter ellipses. Structural Features Generally, The structure of the rotary reverse blowing bag filter consists of the following basic unit (fission, overall combination)

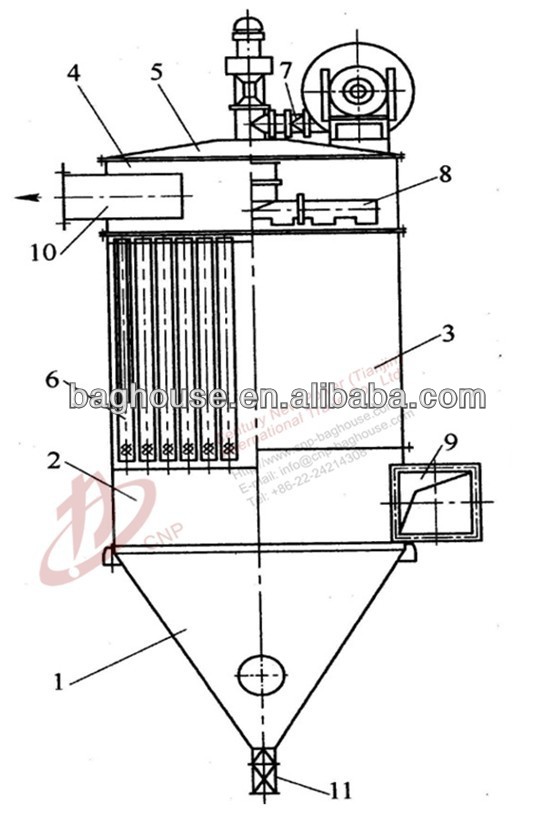

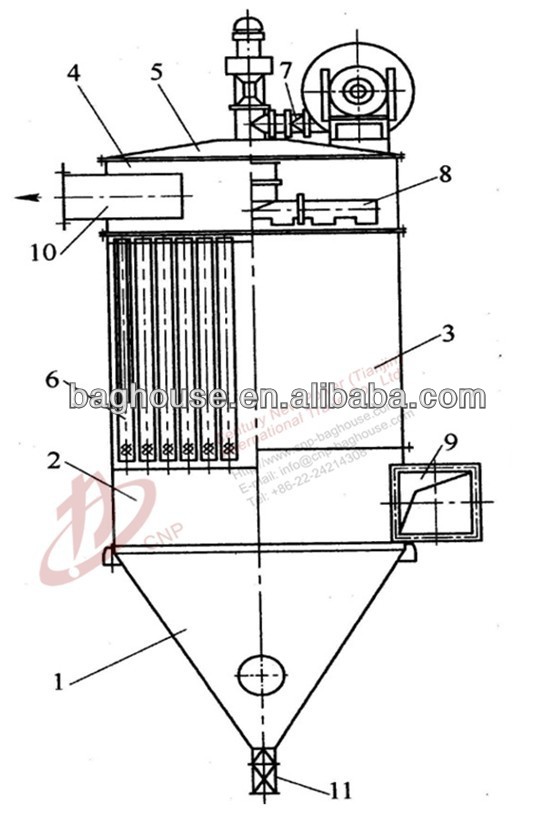

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future. Introduction Revolving reverse blowing bag-type filter, It is using rotating air nozzle, one by one to reverse blow filter bag to dedust bag filter. It has the advantages of simple structure, stable performance, blow air access convenient and small mainte- nance workload. To adopt outside filter type principle, we can divide revolving reverse blowing bag filter according to the different distri- bution in the cross section of the filter bag, flat bag filter, rotary blowback bag filter and rotary blowback bag filter ellipses. Structural Features Generally, The structure of the rotary reverse blowing bag filter consists of the following basic unit (fission, overall combination)  (1) The upper box body.The upper body part includes: the upper barrel, Roof, air outlet and guardrail and vertical ladder. Upper lid for rotary, set a filter bag change and the access manhole;Top lateral lift the roller and seal groove, convenient filter bag replacement compatible with cylinder seal. Guardrail is set on the top cover, along the tube body along a vertical ladder or circular ladder. (2) The central body.Central body part includes: the central cylinder, plate, filter bag and filter bag positioning plate.Filter bag positioning plate, plate positioning after welding, according to the actual location filter bag find is fixed in a lower casing wall, welding. (3)The lower box body. The lower box body part includes: the lower cylinder, ash hopper, manhole, base and star discharger;Into the duct positioning welding on the bottom shell.Base welding on the ash hopper directly, the screw bolt hole position according to the positioning of design;Equipment support according to user needs to match. (4) The blowing system. The blowing system is divided into up and down two forms. Recommended an up blowing system, blow fan is installed directly on the filter head, extraction of atmospheric air or gas net room, circulation organization counter blowing dust; But should pay attention to prevent rain and snow mixed into, pay special attention to counter blowing gas may cause the bomb threat. Revolving reverse blowing bag filter 1 - hopper 2 - down box body;3 - middle box body; 4 - up box body; 5 - the top cover; 6 - filter bag;7 - the blower; 8 - reverse blowing device; 9 - air inlet; 10 - air outlet;11 - discharge valve

(1) The upper box body.The upper body part includes: the upper barrel, Roof, air outlet and guardrail and vertical ladder. Upper lid for rotary, set a filter bag change and the access manhole;Top lateral lift the roller and seal groove, convenient filter bag replacement compatible with cylinder seal. Guardrail is set on the top cover, along the tube body along a vertical ladder or circular ladder. (2) The central body.Central body part includes: the central cylinder, plate, filter bag and filter bag positioning plate.Filter bag positioning plate, plate positioning after welding, according to the actual location filter bag find is fixed in a lower casing wall, welding. (3)The lower box body. The lower box body part includes: the lower cylinder, ash hopper, manhole, base and star discharger;Into the duct positioning welding on the bottom shell.Base welding on the ash hopper directly, the screw bolt hole position according to the positioning of design;Equipment support according to user needs to match. (4) The blowing system. The blowing system is divided into up and down two forms. Recommended an up blowing system, blow fan is installed directly on the filter head, extraction of atmospheric air or gas net room, circulation organization counter blowing dust; But should pay attention to prevent rain and snow mixed into, pay special attention to counter blowing gas may cause the bomb threat. Revolving reverse blowing bag filter 1 - hopper 2 - down box body;3 - middle box body; 4 - up box body; 5 - the top cover; 6 - filter bag;7 - the blower; 8 - reverse blowing device; 9 - air inlet; 10 - air outlet;11 - discharge valve  Revolving reverse blowing system: 1 - vertical reducer device;2 - T - pipe; 3 - the shaft; 4 - rotating disc; 5 - the blowpipe;6 - the nozzle

Revolving reverse blowing system: 1 - vertical reducer device;2 - T - pipe; 3 - the shaft; 4 - rotating disc; 5 - the blowpipe;6 - the nozzle  It is simple and compact structure when the ladder type flat bag in cylinder body decorate. The filter area more larger than. Under the effect of the reverse blowing, trapezoidal flat bag has more large amplitude than the round one. Only one single blowing jar, it can shake off most of the dust. It can improve life of filter bag. Working principle Dust enter into the dust collector by air inlet along the tangent direction, the air flow rotating in the lower cylinder. Under the action of the centrifugal force and gravity, particle size larger dust separation along the wall down into the hopper. And the fine dust rising with air, after radial arrangement of trapezoid (round or oval) filter bag filter, dust be trapped filter bag outside. To purify the gas through the filter bag from net filter bag into the top of the chamber by trachea. Continuously to stay in the outside of the filter bag dust layer thickening, resistance to the set value, automatic start the blower, with enough momentum of blowing, by cantilever duct through a nozzle blow filter bag, filter bag vibration caused by shake filter cake; When the filter bag resistance to lower limit, the blower stop working automatically. In circulation, implementation of precipitator dust, soot and dust collection. Safety facilities: (1) The relief valve. When dust catcher to pulverized coal processing and combustible gas, each device design and install two groups of heavy hammer type safety explosion at least. (2) Ladders, railings and walk filter in the design and installation, must be in conformity with the GB 4053.1 1993 fixed type steel ladder “, ”GB 4053.2 1993 stationary steel inclined ladder”, “4053.23 GB - 1993 fixed industrial protective railings”, “GB 4053.4 1993 stationary industrial steel platform”. (3) The design and installation of dust catcher, scientific temperature control, ensure internal flue gas dust collector temperature above the acid dew point, preventing fouling and condensation bag filter. Matters needing attention: (1) Ash hopper, filter chamber shell, clean room for each manhole door. Explosion door, observation hole between the flange should be embedded into the sealed fill material to tighten the bolt, to prevent air leakage. (2) the ceiling board trapezoid hole should be vertical with the corresponding location on the bottom bracket circle. To prevent skewed gas leak into the frame after the filter bag. (3) Blow slewing transmission mechanism, it should pay attention to vertical in installation. To up and down the arms swing plane and the mouth of the framework to guide line. Keep 2 ~ 4 mm distance, rotating flexible, tuyere turn-over device, a clash of heads with position properly (4) The filter bag from the set of filter bag on the outside, should layering compaction, and prevent leak. Then carefully insert into ceiling board, (note that don’t make the filter bag cut or scratch) tail cone pin inserted into the bottom bracket circle of corresponding location, after the upper guide frame mouth slot neatly aprons with press, pin pressure. (5) Cover the roof, we should try its rotation flexible. Roof and clean outdoor application rubber seal ring junction, by complete sealing under roof. (6) after the installation, filling lubricant to the transmission parts. And then try to check the reducer connection whether reverse turn, such as inversion of rewiring immediately, in order to avoid attaint parts. (7) the transmission parts shall be oiling regularly during the operation, and should be regularly check the jib. Since the reverse blowing control system should be checked regularly, prevent failure. Contact us if you need more details on Industrial Dust Collection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Dust Collection Filter、Bag Type Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

It is simple and compact structure when the ladder type flat bag in cylinder body decorate. The filter area more larger than. Under the effect of the reverse blowing, trapezoidal flat bag has more large amplitude than the round one. Only one single blowing jar, it can shake off most of the dust. It can improve life of filter bag. Working principle Dust enter into the dust collector by air inlet along the tangent direction, the air flow rotating in the lower cylinder. Under the action of the centrifugal force and gravity, particle size larger dust separation along the wall down into the hopper. And the fine dust rising with air, after radial arrangement of trapezoid (round or oval) filter bag filter, dust be trapped filter bag outside. To purify the gas through the filter bag from net filter bag into the top of the chamber by trachea. Continuously to stay in the outside of the filter bag dust layer thickening, resistance to the set value, automatic start the blower, with enough momentum of blowing, by cantilever duct through a nozzle blow filter bag, filter bag vibration caused by shake filter cake; When the filter bag resistance to lower limit, the blower stop working automatically. In circulation, implementation of precipitator dust, soot and dust collection. Safety facilities: (1) The relief valve. When dust catcher to pulverized coal processing and combustible gas, each device design and install two groups of heavy hammer type safety explosion at least. (2) Ladders, railings and walk filter in the design and installation, must be in conformity with the GB 4053.1 1993 fixed type steel ladder “, ”GB 4053.2 1993 stationary steel inclined ladder”, “4053.23 GB - 1993 fixed industrial protective railings”, “GB 4053.4 1993 stationary industrial steel platform”. (3) The design and installation of dust catcher, scientific temperature control, ensure internal flue gas dust collector temperature above the acid dew point, preventing fouling and condensation bag filter. Matters needing attention: (1) Ash hopper, filter chamber shell, clean room for each manhole door. Explosion door, observation hole between the flange should be embedded into the sealed fill material to tighten the bolt, to prevent air leakage. (2) the ceiling board trapezoid hole should be vertical with the corresponding location on the bottom bracket circle. To prevent skewed gas leak into the frame after the filter bag. (3) Blow slewing transmission mechanism, it should pay attention to vertical in installation. To up and down the arms swing plane and the mouth of the framework to guide line. Keep 2 ~ 4 mm distance, rotating flexible, tuyere turn-over device, a clash of heads with position properly (4) The filter bag from the set of filter bag on the outside, should layering compaction, and prevent leak. Then carefully insert into ceiling board, (note that don’t make the filter bag cut or scratch) tail cone pin inserted into the bottom bracket circle of corresponding location, after the upper guide frame mouth slot neatly aprons with press, pin pressure. (5) Cover the roof, we should try its rotation flexible. Roof and clean outdoor application rubber seal ring junction, by complete sealing under roof. (6) after the installation, filling lubricant to the transmission parts. And then try to check the reducer connection whether reverse turn, such as inversion of rewiring immediately, in order to avoid attaint parts. (7) the transmission parts shall be oiling regularly during the operation, and should be regularly check the jib. Since the reverse blowing control system should be checked regularly, prevent failure. Contact us if you need more details on Industrial Dust Collection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Dust Collection Filter、Bag Type Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Please click following picture to see our more information about cyclone and bag type Dust Collector equipment introduction:

Please click following picture to see our more information about cyclone and bag type Dust Collector equipment introduction:  Product Description Industry application impulse bag type dust collector

Product Description Industry application impulse bag type dust collector  DMC pulse bag filter is a kind of small and medium-sized pulse jet dust collector. Reasonable structure design to realize efficient dust removal and small resistance running. To adopt pulse blowing dust, soot cleaning effect is better. The advantage is reliable operation, easy maintenance and management. This kind of bag filter always widely used in cement, metallurgy, electric power, chemical and other industries of dust gas purification and material recycling. DMC pulse bag dust catcher are composed by the filter chamber housing, clean air chamber enclosure, Filter bag and Filter cage, pulse injection device, ash hopper, Screw conveyor and discharger, etc. Structure Composition DMC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, Pulse Valve, screw conveyor, discharge valve, electrical control cabinet, air compressor, Filter Bag, filter cages, etc. All parts are made according to the national standards and customer's requirement. Blowing system: the spray pipe, Pulse valve, venturi, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: motor, reducer, screw conveyer, unloader, etc. Working principle

DMC pulse bag filter is a kind of small and medium-sized pulse jet dust collector. Reasonable structure design to realize efficient dust removal and small resistance running. To adopt pulse blowing dust, soot cleaning effect is better. The advantage is reliable operation, easy maintenance and management. This kind of bag filter always widely used in cement, metallurgy, electric power, chemical and other industries of dust gas purification and material recycling. DMC pulse bag dust catcher are composed by the filter chamber housing, clean air chamber enclosure, Filter bag and Filter cage, pulse injection device, ash hopper, Screw conveyor and discharger, etc. Structure Composition DMC series pulse bag filter are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, Pulse Valve, screw conveyor, discharge valve, electrical control cabinet, air compressor, Filter Bag, filter cages, etc. All parts are made according to the national standards and customer's requirement. Blowing system: the spray pipe, Pulse valve, venturi, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time. Ash hopper and ash discharge part: motor, reducer, screw conveyer, unloader, etc. Working principle  Sales Performance As the best-selling brand of small size dust collector of our company, DMC pulse bag dust collector has the device of the quantity of goods more than 500 units so far this year 2013. Which is used for cement plant library, belt corridor for 83 units; used in mining, building materials industries of the crusher, belt conveyor unloading point for 75 units; used in complete set of packaging machine for 120 sets; used in chemical industry of small vibrating sieve for 65 sets; used in sieve drum filter, mechanical machining, grinding machine, sandblasting room and other industries for 150 sets; DMC pulse bag dust collector is favored by many industrial customer friends. The main reason is the reasonable structural design, reliable performance, easy maintenance and management. As an example: In 2010 year, we provide DMC - 183 type bag dust collector for AL Haribiaha cement plant, since the installation run till now, operation is very stable, soot cleaning effect is very good!

Sales Performance As the best-selling brand of small size dust collector of our company, DMC pulse bag dust collector has the device of the quantity of goods more than 500 units so far this year 2013. Which is used for cement plant library, belt corridor for 83 units; used in mining, building materials industries of the crusher, belt conveyor unloading point for 75 units; used in complete set of packaging machine for 120 sets; used in chemical industry of small vibrating sieve for 65 sets; used in sieve drum filter, mechanical machining, grinding machine, sandblasting room and other industries for 150 sets; DMC pulse bag dust collector is favored by many industrial customer friends. The main reason is the reasonable structural design, reliable performance, easy maintenance and management. As an example: In 2010 year, we provide DMC - 183 type bag dust collector for AL Haribiaha cement plant, since the installation run till now, operation is very stable, soot cleaning effect is very good!  Specifications Performance Parameter DMC pulse jet bag filter technical parameters:

Specifications Performance Parameter DMC pulse jet bag filter technical parameters:  Due to the different industries, the DMC pulse bag filter has the different applicable conditions. Please be sure to tell us about your needs, we are very happy to provide surveying and design for you by free, to achieve the best and safety solution of dust collection. Trade Shows f application

Due to the different industries, the DMC pulse bag filter has the different applicable conditions. Please be sure to tell us about your needs, we are very happy to provide surveying and design for you by free, to achieve the best and safety solution of dust collection. Trade Shows f application

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future. Introduction Revolving reverse blowing bag-type filter, It is using rotating air nozzle, one by one to reverse blow filter bag to dedust bag filter. It has the advantages of simple structure, stable performance, blow air access convenient and small mainte- nance workload. To adopt outside filter type principle, we can divide revolving reverse blowing bag filter according to the different distri- bution in the cross section of the filter bag, flat bag filter, rotary blowback bag filter and rotary blowback bag filter ellipses. Structural Features Generally, The structure of the rotary reverse blowing bag filter consists of the following basic unit (fission, overall combination)

Our Services 1. Enquiries quickly reply within 24 hours. 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved. 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design. 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle. 5. The bag filter equipment over 20 years working life. 6. Associated with equipment spare parts, ensure the replacement parts within 20 years. 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production. 8. Ensure easy operation and absolutely no worries about future. Introduction Revolving reverse blowing bag-type filter, It is using rotating air nozzle, one by one to reverse blow filter bag to dedust bag filter. It has the advantages of simple structure, stable performance, blow air access convenient and small mainte- nance workload. To adopt outside filter type principle, we can divide revolving reverse blowing bag filter according to the different distri- bution in the cross section of the filter bag, flat bag filter, rotary blowback bag filter and rotary blowback bag filter ellipses. Structural Features Generally, The structure of the rotary reverse blowing bag filter consists of the following basic unit (fission, overall combination)  (1) The upper box body.The upper body part includes: the upper barrel, Roof, air outlet and guardrail and vertical ladder. Upper lid for rotary, set a filter bag change and the access manhole;Top lateral lift the roller and seal groove, convenient filter bag replacement compatible with cylinder seal. Guardrail is set on the top cover, along the tube body along a vertical ladder or circular ladder. (2) The central body.Central body part includes: the central cylinder, plate, filter bag and filter bag positioning plate.Filter bag positioning plate, plate positioning after welding, according to the actual location filter bag find is fixed in a lower casing wall, welding. (3)The lower box body. The lower box body part includes: the lower cylinder, ash hopper, manhole, base and star discharger;Into the duct positioning welding on the bottom shell.Base welding on the ash hopper directly, the screw bolt hole position according to the positioning of design;Equipment support according to user needs to match. (4) The blowing system. The blowing system is divided into up and down two forms. Recommended an up blowing system, blow fan is installed directly on the filter head, extraction of atmospheric air or gas net room, circulation organization counter blowing dust; But should pay attention to prevent rain and snow mixed into, pay special attention to counter blowing gas may cause the bomb threat. Revolving reverse blowing bag filter 1 - hopper 2 - down box body;3 - middle box body; 4 - up box body; 5 - the top cover; 6 - filter bag;7 - the blower; 8 - reverse blowing device; 9 - air inlet; 10 - air outlet;11 - discharge valve

(1) The upper box body.The upper body part includes: the upper barrel, Roof, air outlet and guardrail and vertical ladder. Upper lid for rotary, set a filter bag change and the access manhole;Top lateral lift the roller and seal groove, convenient filter bag replacement compatible with cylinder seal. Guardrail is set on the top cover, along the tube body along a vertical ladder or circular ladder. (2) The central body.Central body part includes: the central cylinder, plate, filter bag and filter bag positioning plate.Filter bag positioning plate, plate positioning after welding, according to the actual location filter bag find is fixed in a lower casing wall, welding. (3)The lower box body. The lower box body part includes: the lower cylinder, ash hopper, manhole, base and star discharger;Into the duct positioning welding on the bottom shell.Base welding on the ash hopper directly, the screw bolt hole position according to the positioning of design;Equipment support according to user needs to match. (4) The blowing system. The blowing system is divided into up and down two forms. Recommended an up blowing system, blow fan is installed directly on the filter head, extraction of atmospheric air or gas net room, circulation organization counter blowing dust; But should pay attention to prevent rain and snow mixed into, pay special attention to counter blowing gas may cause the bomb threat. Revolving reverse blowing bag filter 1 - hopper 2 - down box body;3 - middle box body; 4 - up box body; 5 - the top cover; 6 - filter bag;7 - the blower; 8 - reverse blowing device; 9 - air inlet; 10 - air outlet;11 - discharge valve  Revolving reverse blowing system: 1 - vertical reducer device;2 - T - pipe; 3 - the shaft; 4 - rotating disc; 5 - the blowpipe;6 - the nozzle

Revolving reverse blowing system: 1 - vertical reducer device;2 - T - pipe; 3 - the shaft; 4 - rotating disc; 5 - the blowpipe;6 - the nozzle  It is simple and compact structure when the ladder type flat bag in cylinder body decorate. The filter area more larger than. Under the effect of the reverse blowing, trapezoidal flat bag has more large amplitude than the round one. Only one single blowing jar, it can shake off most of the dust. It can improve life of filter bag. Working principle Dust enter into the dust collector by air inlet along the tangent direction, the air flow rotating in the lower cylinder. Under the action of the centrifugal force and gravity, particle size larger dust separation along the wall down into the hopper. And the fine dust rising with air, after radial arrangement of trapezoid (round or oval) filter bag filter, dust be trapped filter bag outside. To purify the gas through the filter bag from net filter bag into the top of the chamber by trachea. Continuously to stay in the outside of the filter bag dust layer thickening, resistance to the set value, automatic start the blower, with enough momentum of blowing, by cantilever duct through a nozzle blow filter bag, filter bag vibration caused by shake filter cake; When the filter bag resistance to lower limit, the blower stop working automatically. In circulation, implementation of precipitator dust, soot and dust collection. Safety facilities: (1) The relief valve. When dust catcher to pulverized coal processing and combustible gas, each device design and install two groups of heavy hammer type safety explosion at least. (2) Ladders, railings and walk filter in the design and installation, must be in conformity with the GB 4053.1 1993 fixed type steel ladder “, ”GB 4053.2 1993 stationary steel inclined ladder”, “4053.23 GB - 1993 fixed industrial protective railings”, “GB 4053.4 1993 stationary industrial steel platform”. (3) The design and installation of dust catcher, scientific temperature control, ensure internal flue gas dust collector temperature above the acid dew point, preventing fouling and condensation bag filter. Matters needing attention: (1) Ash hopper, filter chamber shell, clean room for each manhole door. Explosion door, observation hole between the flange should be embedded into the sealed fill material to tighten the bolt, to prevent air leakage. (2) the ceiling board trapezoid hole should be vertical with the corresponding location on the bottom bracket circle. To prevent skewed gas leak into the frame after the filter bag. (3) Blow slewing transmission mechanism, it should pay attention to vertical in installation. To up and down the arms swing plane and the mouth of the framework to guide line. Keep 2 ~ 4 mm distance, rotating flexible, tuyere turn-over device, a clash of heads with position properly (4) The filter bag from the set of filter bag on the outside, should layering compaction, and prevent leak. Then carefully insert into ceiling board, (note that don’t make the filter bag cut or scratch) tail cone pin inserted into the bottom bracket circle of corresponding location, after the upper guide frame mouth slot neatly aprons with press, pin pressure. (5) Cover the roof, we should try its rotation flexible. Roof and clean outdoor application rubber seal ring junction, by complete sealing under roof. (6) after the installation, filling lubricant to the transmission parts. And then try to check the reducer connection whether reverse turn, such as inversion of rewiring immediately, in order to avoid attaint parts. (7) the transmission parts shall be oiling regularly during the operation, and should be regularly check the jib. Since the reverse blowing control system should be checked regularly, prevent failure. Contact us if you need more details on Industrial Dust Collection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Dust Collection Filter、Bag Type Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

It is simple and compact structure when the ladder type flat bag in cylinder body decorate. The filter area more larger than. Under the effect of the reverse blowing, trapezoidal flat bag has more large amplitude than the round one. Only one single blowing jar, it can shake off most of the dust. It can improve life of filter bag. Working principle Dust enter into the dust collector by air inlet along the tangent direction, the air flow rotating in the lower cylinder. Under the action of the centrifugal force and gravity, particle size larger dust separation along the wall down into the hopper. And the fine dust rising with air, after radial arrangement of trapezoid (round or oval) filter bag filter, dust be trapped filter bag outside. To purify the gas through the filter bag from net filter bag into the top of the chamber by trachea. Continuously to stay in the outside of the filter bag dust layer thickening, resistance to the set value, automatic start the blower, with enough momentum of blowing, by cantilever duct through a nozzle blow filter bag, filter bag vibration caused by shake filter cake; When the filter bag resistance to lower limit, the blower stop working automatically. In circulation, implementation of precipitator dust, soot and dust collection. Safety facilities: (1) The relief valve. When dust catcher to pulverized coal processing and combustible gas, each device design and install two groups of heavy hammer type safety explosion at least. (2) Ladders, railings and walk filter in the design and installation, must be in conformity with the GB 4053.1 1993 fixed type steel ladder “, ”GB 4053.2 1993 stationary steel inclined ladder”, “4053.23 GB - 1993 fixed industrial protective railings”, “GB 4053.4 1993 stationary industrial steel platform”. (3) The design and installation of dust catcher, scientific temperature control, ensure internal flue gas dust collector temperature above the acid dew point, preventing fouling and condensation bag filter. Matters needing attention: (1) Ash hopper, filter chamber shell, clean room for each manhole door. Explosion door, observation hole between the flange should be embedded into the sealed fill material to tighten the bolt, to prevent air leakage. (2) the ceiling board trapezoid hole should be vertical with the corresponding location on the bottom bracket circle. To prevent skewed gas leak into the frame after the filter bag. (3) Blow slewing transmission mechanism, it should pay attention to vertical in installation. To up and down the arms swing plane and the mouth of the framework to guide line. Keep 2 ~ 4 mm distance, rotating flexible, tuyere turn-over device, a clash of heads with position properly (4) The filter bag from the set of filter bag on the outside, should layering compaction, and prevent leak. Then carefully insert into ceiling board, (note that don’t make the filter bag cut or scratch) tail cone pin inserted into the bottom bracket circle of corresponding location, after the upper guide frame mouth slot neatly aprons with press, pin pressure. (5) Cover the roof, we should try its rotation flexible. Roof and clean outdoor application rubber seal ring junction, by complete sealing under roof. (6) after the installation, filling lubricant to the transmission parts. And then try to check the reducer connection whether reverse turn, such as inversion of rewiring immediately, in order to avoid attaint parts. (7) the transmission parts shall be oiling regularly during the operation, and should be regularly check the jib. Since the reverse blowing control system should be checked regularly, prevent failure. Contact us if you need more details on Industrial Dust Collection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Dust Collection Filter、Bag Type Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Dust collector > Round filter

Premium Related Products

Other Products

Hot Products

Dust collector machine and baghouse filterBag Type Wood Washable Pocket FiltersComfortable cyclone separator priceMini cyclone separator dust collector24v miniature cheap solenoid pulse ValveCement grain pellet ice shaftless sand flexible screw conveyorBulk cement trailer self unloading equipment parts the PU coated Airslide Aeration hoseHigh temperature dust exhaust fan dust collector fan blowerAramid Airslide Fabric / BeltBulk material bottom rotary discharge valveOrgano silicone filter bag cageSulphide dust treatment PPS low price filter bagPolyester filter fabric stainless steel fiber needle feltCylindrical cyclone pulse jet silo dust collection bag filterCement industry plant dust pollution control the dust collector pulse vibration bag filterSimple bag filter AIO machine portable wood dust collector